Excel Weighbridge

Price 220000.00 INR/ Piece

Excel Weighbridge Specification

- Material

- Steel

- Loading Capacity

- 10 to 150 Metric Ton

- Display Type

- LED

- Structure

- Flat

- Voltage

- 150 Volt (v)

- Product Type

- Excel Weighbridge

Excel Weighbridge Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 5 Pieces Per Month

- Delivery Time

- 15 Week

- Main Domestic Market

- Maharashtra, Rajasthan, Madhya Pradesh

About Excel Weighbridge

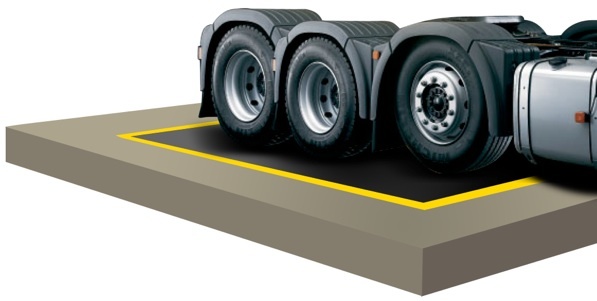

The weigh bridge now fully integrated with their Excel spreadsheet, weighing goods in and out has been speeded up considerably and accuracy has been improved.

Product details

|

Brand |

Sensotech |

|

Power Supply |

230 V AC |

|

Accuracy |

Electronic |

Reliable Weighing Capacity

With its impressive load capacity of 10 to 150 metric tons, the Excel Weighbridge is engineered to manage a wide spectrum of vehicles and goods. Its flat structure and steel construction provide both stability and resilience, ensuring precise weight readings for essential operations.

Durable Construction

Crafted entirely from steel, the weighbridge stands up to heavy use and demanding environments. The flat platform design enables smooth, easy loading and unloading, helping to streamline weighing processes in busy settings.

User-Friendly Display

Equipped with a bright LED display, the Excel Weighbridge ensures weights are instantly and clearly visible to operators. This reduces the risk of errors and supports swift decision-making, essential for fast-paced industrial applications.

FAQs of Excel Weighbridge:

Q: How do I operate the Excel Weighbridge once it is installed?

A: Operating the Excel Weighbridge is straightforward. Simply position the vehicle or load onto the flat steel platform, and the weight is automatically displayed on the bright LED screen. The system functions at 150 volts, making it energy-efficient and reliable.Q: What benefits does the steel construction of the weighbridge provide?

A: The all-steel structure ensures exceptional durability, resistance to harsh environments, and a stable platform for accurate weight readings. This design prolongs lifespan and minimizes maintenance needs, making it cost-effective for industrial use.Q: When should I schedule maintenance for my Excel Weighbridge?

A: Regular maintenance is recommended every six months, or as advised by the manufacturer and service provider. Routine checks help maintain accuracy, prevent wear, and ensure the weighbridge continues to function optimally.Q: Where is the Excel Weighbridge manufactured and supported?

A: The Excel Weighbridge is manufactured, supplied, and supported in India. Local service providers ensure prompt assistance with installation, calibration, and after-sales support.Q: What is the installation process for this weighbridge?

A: Installation involves preparing a level surface, positioning the flat steel structure, and connecting it to a 150-volt power supply. Certified technicians will calibrate the LED display and ensure the weighbridge is operational and compliant with safety standards.Q: How is the weighbridge typically used in commercial or industrial environments?

A: It is commonly used to weigh loaded and unloaded trucks, monitor logistics operations, and ensure accurate billing based on cargo weight. Its flat, robust surface accommodates various vehicle sizes, enhancing operational efficiency.Q: What are the key advantages of using a weighbridge with a flat structure and LED display?

A: A flat structure ensures easy access for vehicles and smooth loading, while the LED display provides instant, clear weight readouts, reducing human error and expediting the weighing process.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Electronic Weighbridge Category

Pit Type Weighbridge

Price 1350000 INR / Piece

Minimum Order Quantity : 1 Piece

Voltage : 150 Volt (v)

Loading Capacity : 10Mt to 150 Mt. Metric Ton

Material : Steel

Size : Customized

Pitless Weighbridge

Price 1350000 INR / Piece

Minimum Order Quantity : 1 Piece

Voltage : 150 Volt (v)

Loading Capacity : 10 to 150 Metric Ton

Material : Steel

Truck Electronic Weighbridge

Minimum Order Quantity : 1 Unit

Voltage : 230 Volt (v)

Loading Capacity : 150 Tonne

Material : Mild Steel

Size : 20 m

Fully Electronic Weighbridge

Minimum Order Quantity : 1 Unit

Voltage : 230 Volt (v)

Loading Capacity : 120 Metric Ton

Material : Mild Steel

Size : Standard

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS